Greetings everyone! I hope you all enjoyed Cinco de Mayo last week. We celebrated here at the Mishimoto R&D Center with a salsa and dip competition - let me tell you, many of our team members have just as much talent in the kitchen as they do in the design center (and those of us who don't were grateful taste testers).

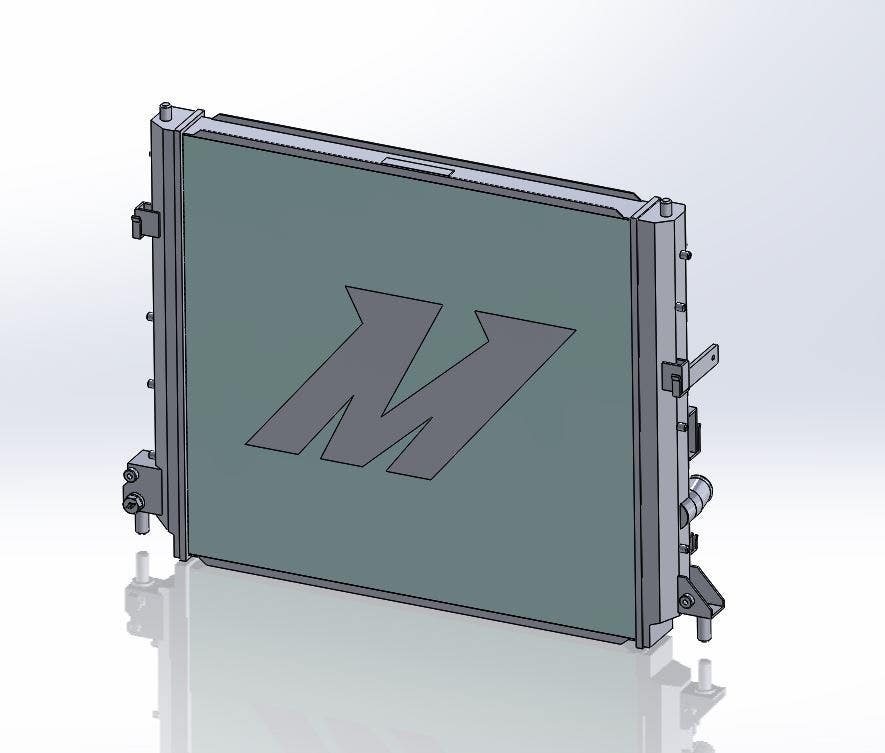

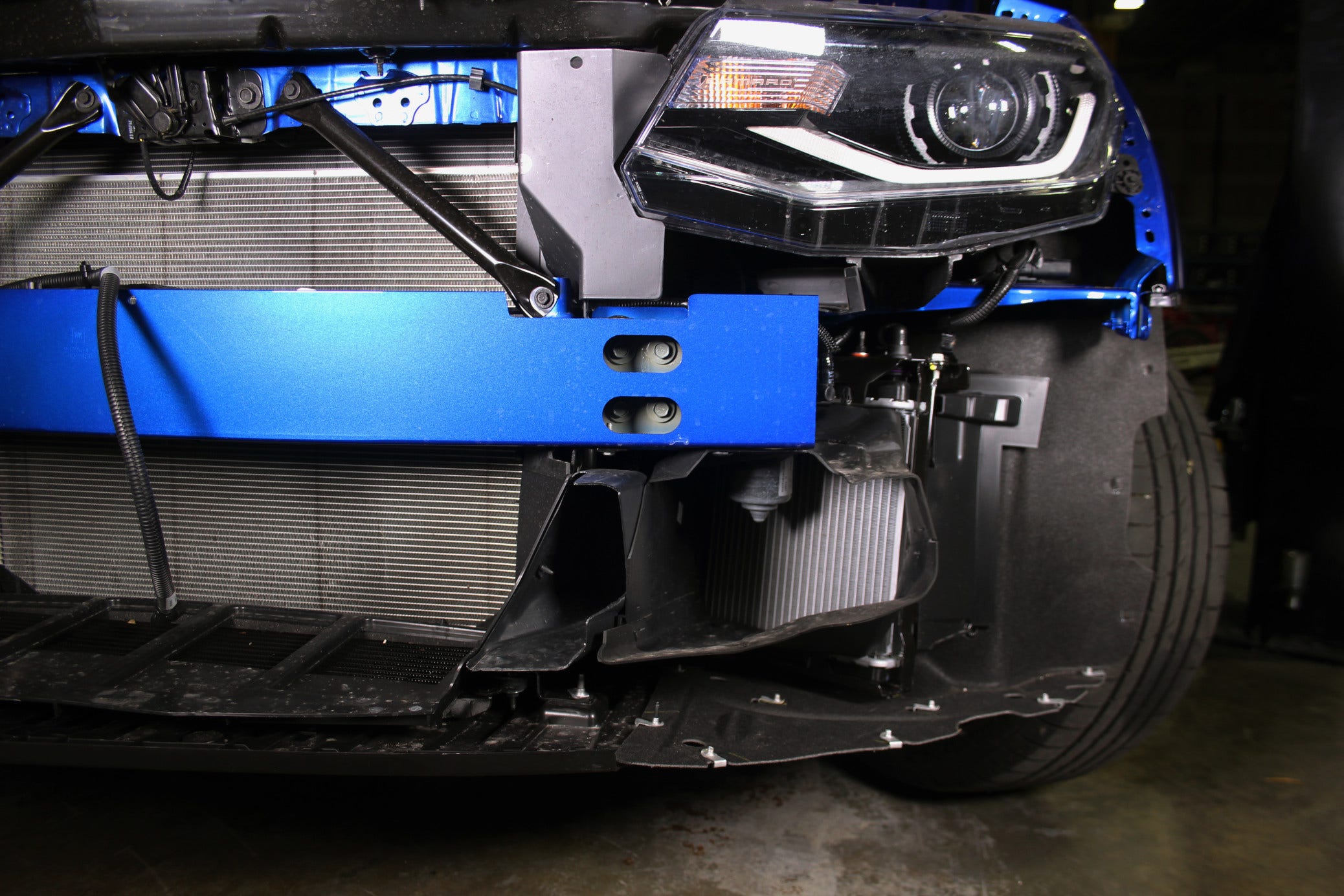

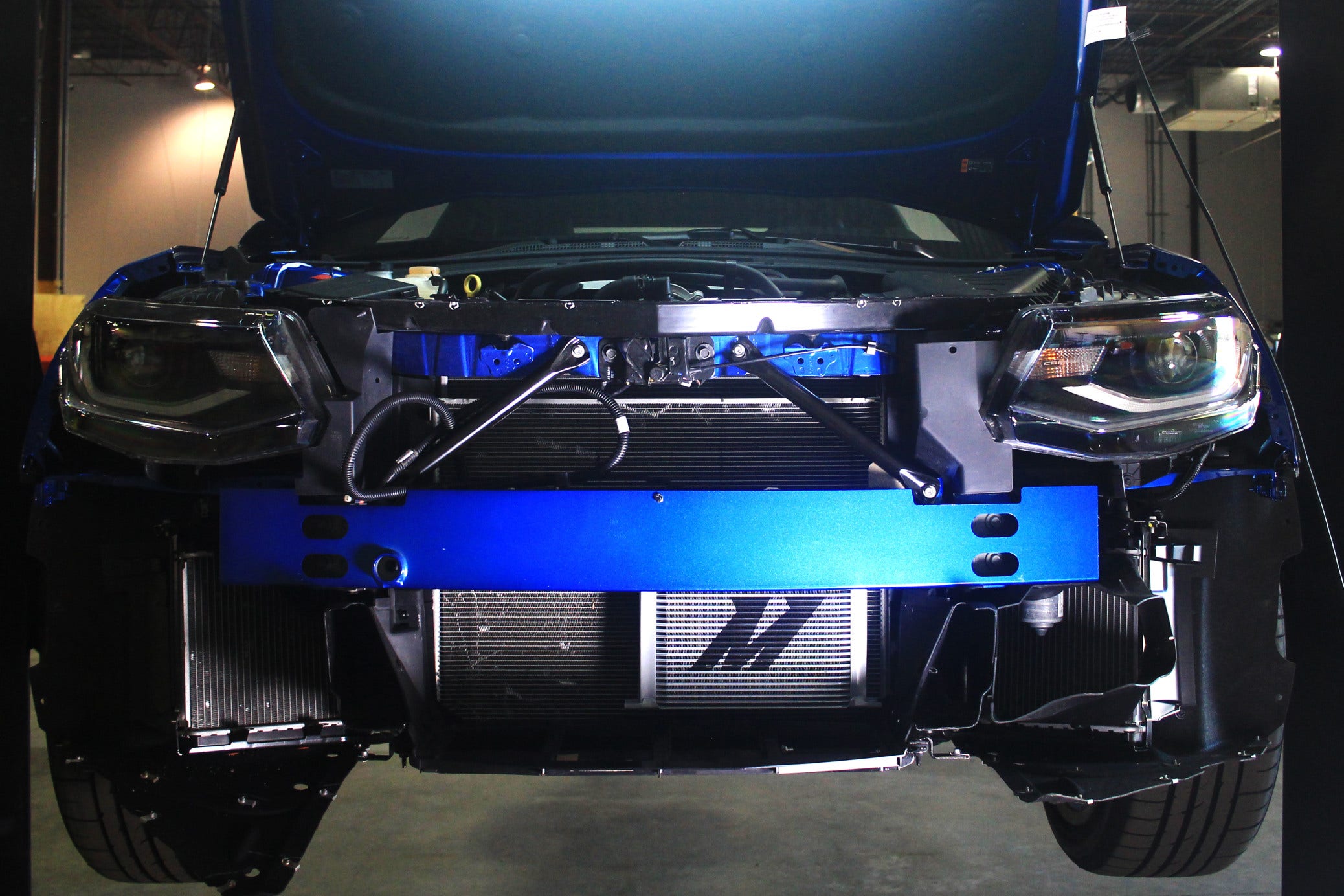

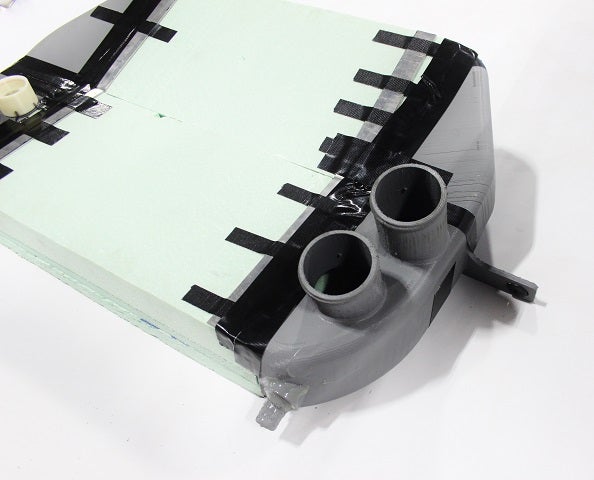

Though our schedules have been VERY busy with projects, the beginning of show season, and maybe a few siestas here and there (definitely a necessity after all those corn chips!), our engineers have been able to squeeze in some time designing our improved aluminum 2016 Camaro SS radiator. I am here to show you the fruits of their labors! Let's take a peek at what they created.

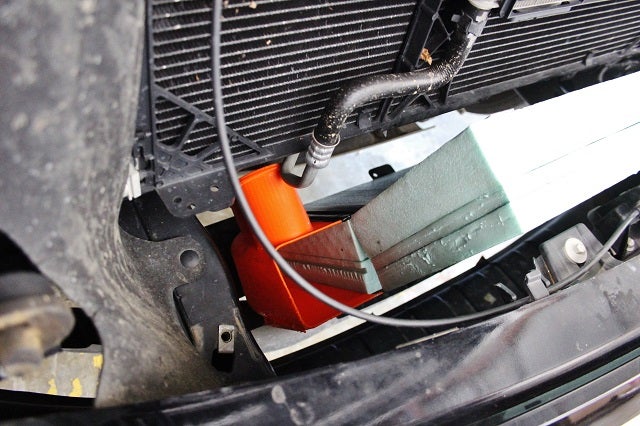

2016 Camaro radiator - Front View

" width="640" height="426">

" width="640" height="426">