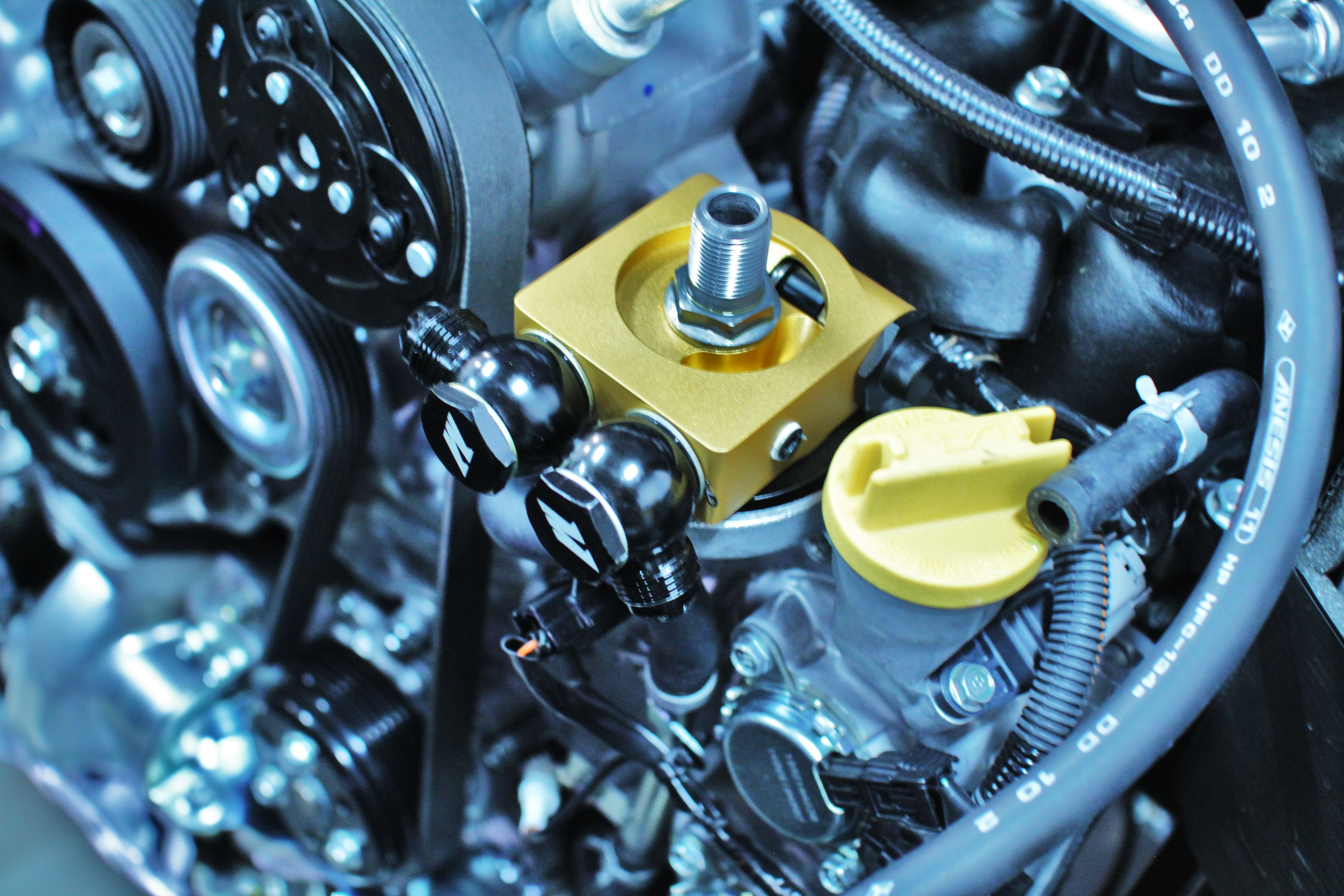

Interested in purchasing our Subaru battery tie-down? Check out more details on our product page linked below!

Mishimoto Subaru CNC Battery Tie Down

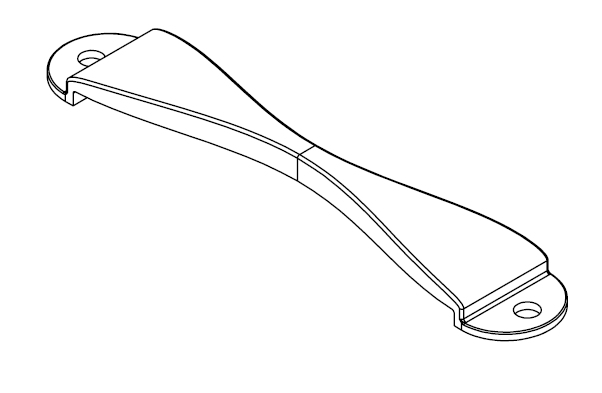

Mishimoto is not only interested in improving the performance, reliability, and power output of your new Subaru, but we also care about aesthetics. Small touches in the engine bay can make a big impact on the overall appearance and also provide a sense of personalization. Our first targeted component is the battery tie-down. The stock tie-down is rather bland, its main purpose being functionality, which is fine for a stock unit. For those looking to upgrade, a stylish aluminum replacement is ideal. In case you haven't yet peered into the engine bay of your "15, here is what the stock tie-down looks like.