Are you a nerd for up-and-coming tech? I am. Technology is awesome. Let's just start there. It's wild to think that we are approaching the 10-year anniversary of the iPhone's first introduction (June 29, 2007, per the all-knowing Wikipedia). As we enter 2017, autonomous vehicles are gaining mainstream traction, rockets can (sort of) land themselves intact, human

BLOG CATEGORIES

- The Ultimate Guide For Intercooler Selection

- Air-to-Water vs. Air-to-Air Intercooling

- The Top 3 Things to Look for When Choosing an Intercooler

- 12 Ways To Prepare Your Diesel For Winter

- Equipment Profiles

- Coolant Overflow Tanks vs. Expansion Tanks

- Coolant Basics

- What Is Blow By?

- Do Try This at Home – 10 Easy Updates You Can Do This Weekend

- Horsepower and You

- Air Filters: Dry vs Oiled

- Air Metering 101: Maf vs. Speed Density

- Turbocharging vs. Supercharging

- Blow Off Valves Explained

- Ford Bronco 2.7L Performance Intercooler, 2021+

- Ford Bronco 2.3 Performance Intercooler, 2021+

- Ford Bronco 2.3L/2.7L Stock Performance Stock Location Intercooler, 2021+

- Ford Bronco 2.3L Performance Intercooler Pipes, 2021+

- Ford Bronco 2.7L Performance Intercooler Pipes, 2021+

- Ford Bronco 2.3L/2.7L Borne Off-Road Snorkel, 2021+

- Ford Bronco 2.7L Performance Intake, 2021+

- Ford Bronco 2.3L Performance Intake, 2021+

- Ford Bronco 2.7L Baffled Oil Catch Can

- Ford Bronco 2.7L Baffled Oil Catch Can, PCV-Side, 2021+

- Ford Bronco 2.3L Baffled Oil Catch Can, 2021+

- BMW F8X M3/M3 Baffled Oil Catch Can Kit, CCV Side, 2015-2020

- BMW M2C/M3/M4 DCT Transmission Cooler, 2015-2020

- BMW F8X M3/M4 Direct Fit Oil Cooler, 2015-2020

- BMW F8X M2C/M3/M4 Performance Heat Exchanger, 2015-2020

- BMW F8X M2C/M3/M4 Charge Pipe Kit, 2015-2020

- BMW F8X M2C/M3/M4 Performance Air-to-Water Intercooler, 2015-2020

euro

-

Posted: December 15, 2016Categories: Volkswagen GTI Catch Can 2015+Continue Reading »

-

Posted: November 30, 2016Categories: Volkswagen GTI Catch Can 2015+Continue Reading »

Oil catch cans are a hotly debated topic, yet one fact is still irrefutable; oil blow-by will always be a real byproduct of the modern direct-injection engine. Intakes, charge pipes, and turbos all come into contact with the stuff over time. Sometimes, even newer, low mileage vehicles develop blow-by issues. With direct injection, fuel is injected directly into the cylinders, eventually resulting in carbon buildup on the valves. This was not an issue with port injection, since fuel injectors were placed in the intake manifold. The air-fuel mixture is sprayed directly on the valves, essentially cleaning them each time an injector fired.

Carbon and oil buildup in direct-injection engines can negatively impact vital engine components and can result in an expensive fix later down the road. I can go into long, excruciatingly deep detail about the dangers of blow-by, but I've given you the basics of what you should know. For more information, I strongly suggest that you take a look

-

Posted: December 29, 2015Categories: Volkswagen GTI Intake 2015+Continue Reading »

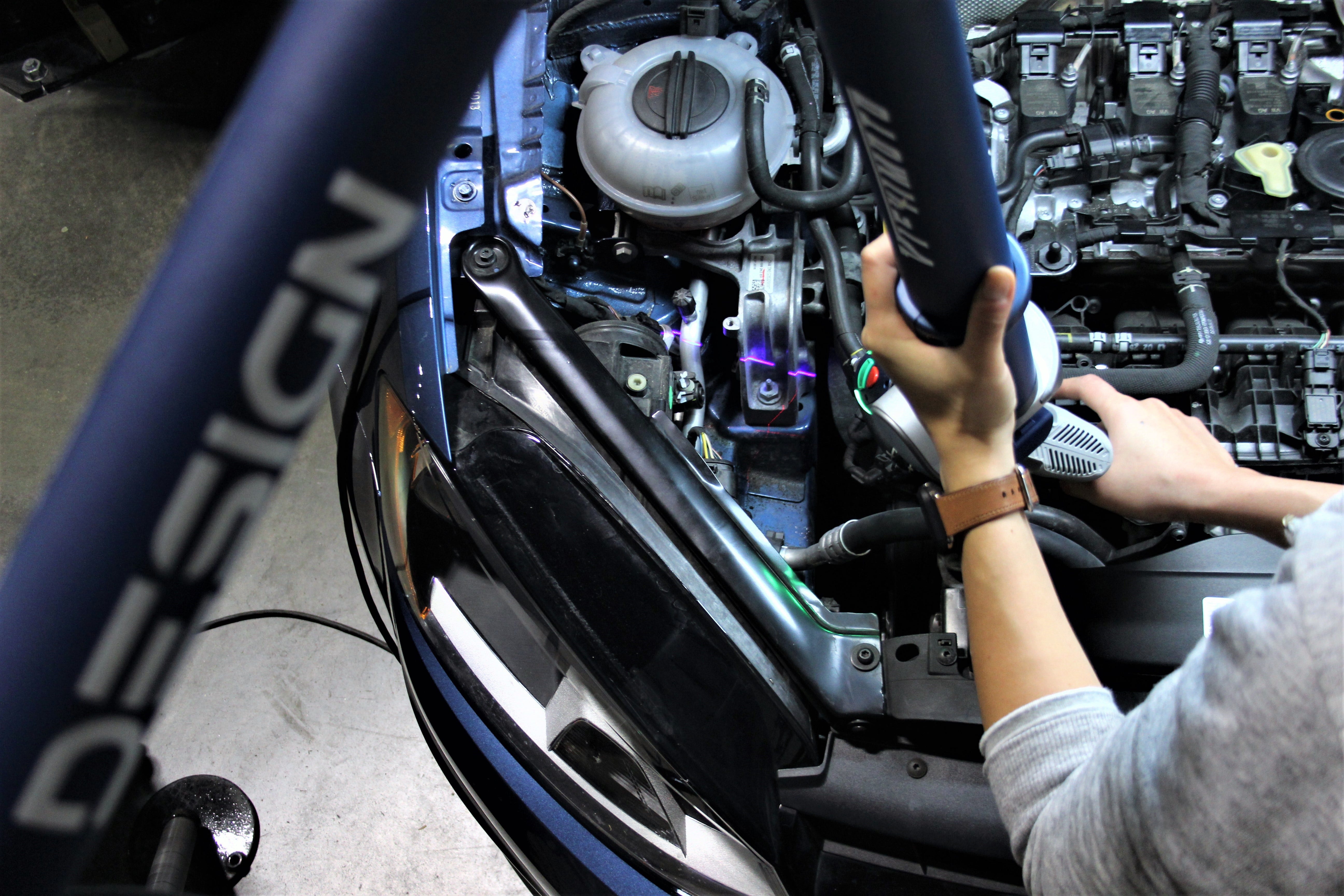

Great news from the Mishimoto garage! We have tested and fitted the final iteration of our airbox design for this prototype MK7 intake. We made some minor adjustments for fitment and ease of installation, but more on that later. This has been an interesting project from the start because of the uniqueness of this box design - check it out!

Final Intake System

Once this prototype system was ready to go, we prepared it for final fitting into the MK7. The next step is paint! The final products will be powder coated, with the intake pipe color options ranging from wrinkle black/red powdercoat or chrome polish. So the painted parts below are just for visualization purposes.

Prototype MK7 parts drying from paint -

Posted: November 20, 2015Categories: Volkswagen GTI Intake 2015+Continue Reading »

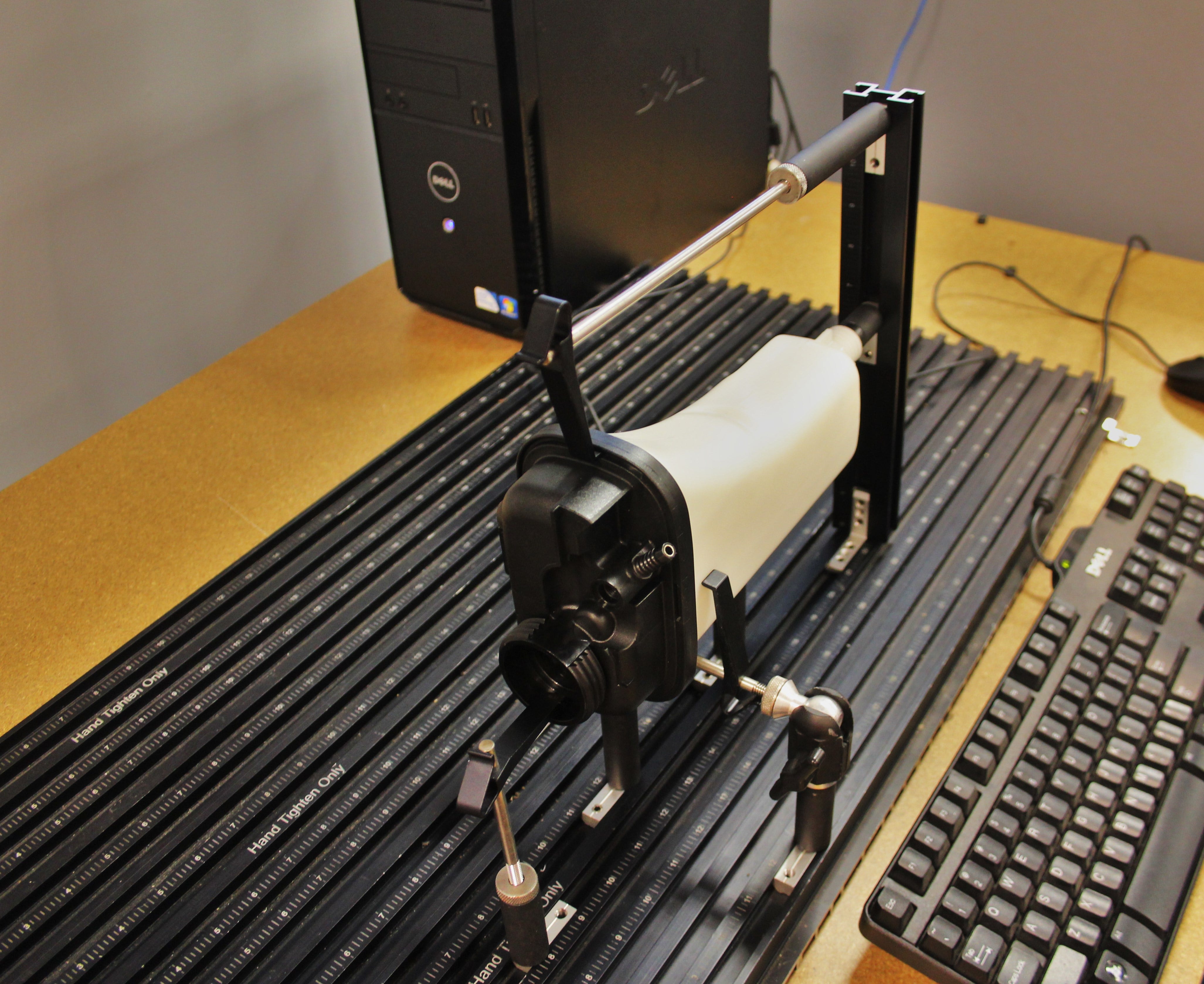

The time has come to test our prototype design for the MK7 intake. After weeks of designing and fabrication, the prototype for this VW is now ready to hit our Dynapack dynamometer so we can collect some data.

Testing these prototype MK7 GTI parts for overall power output gains over stock is important, so that's the first thing we needed to figure out. The larger diameter piping compared to the stock system provides increased airflow that will have a direct impact on improving power output. This car did happen to come with an aftermarket stage 1 tune on it, so we tested our intake with that software upgrade.

-

Posted: October 22, 2015Categories: Volkswagen GTI Intake 2015+Continue Reading »

We've got hot hatch fever! One of the newest vehicles to grace our garage, which happens to be our 3rd hatch for intake development, is the new 2015 VW GTI. Although Volkswagen was far from the first company with a hot hatch in its lineup, it was one of the first companies to really push the popularity of the design. VW is synonymous with the term "hot hatch" to most automotive enthusiasts. With the emergence of VW's newest GTI, it's time for us at Mishimoto to design our own intake for this turbocharged 2.0L engine.

GTI arriving at the shop!

Goals

Newer GTIs can either come with or without a Secondary Air Injection (SAI) pipe. Basically, this is a system that forces more air into the exhaust during

-

Posted: April 17, 2015Categories: BMW 3-Series E36 Electric Fan Shroud 1992-1999Continue Reading »

Interested in picking up our E36 fan shroud? Check out the full details on this kit on our product page!

Mishimoto BMW E36 Performance Fan Shroud Kit!

Our final prototype is complete and looks fantastic. The fan mount is constructed from 1/8" steel that has been cut to a specific shape allowing for additional airflow through the radiator core at speed. Additionally, the mount is powder coated black to provide a durable finish. As noted in our last post, we tested this unit extensively with our 16" fan to ensure that coolant temperatures were properly regulated during both idle and all driving conditions.

Check out a few shots of the mount!

Final -

Posted: March 06, 2015Categories: BMW 3-Series E36 Electric Fan Shroud 1992-1999Continue Reading »

Interested in picking up our E36 fan shroud? Check out the full details on this kit on our product page!

Mishimoto BMW E36 Performance Fan Shroud Kit!

E36 M3 on dyno

First Prototype Testing

When we left off last time we were exploring our first prototype design. This unit is a traditional aluminum fan shroud with air flaps to improve core airflow at speed. Once we had a working prototype, we decided to perform some idle testing to see how well our single electric fan would perform on a mostly stock E36 M3.

To get started, we began removing the stock setup.

-

Posted: March 02, 2015Categories: BMW 3-Series E36 Expansion Tank 1992-1999Continue Reading »

Interested in picking up this aluminum E36 expansion tank? Check out our product page linked below!

BMW E36 Aluminum Coolant Expansion Tank!

Historically, BMW vehicles have been plagued with rather frequent cooling system failures. A majority of these failures are a result of the use of plastic components in a high-temperature application. Although failure isn't immediate, over time the frequent heat cycling of these plastic components results in increased fragility, fatigue, and eventual failure.

A few components we see failing on E36 models include the radiator end tanks, radiator expansion tank, and the mechanical fan. We already offer two aluminum radiator options, and we have an electric-fan conversion kit in the works. An expansion tank is our last stop for product development on the E36 (for now). We have had numerous requests

-

Posted: January 15, 2015Categories: BMW 3-Series E36 Electric Fan Shroud 1992-1999Continue Reading »

Interested in picking up our E36 fan shroud? Check out the full details on this kit on our product page!

Mishimoto BMW E36 Performance Fan Shroud Kit!

E36 M3 test vehicle

Cooling systems on older BMW models have been recognized as a frequent failure point requiring regular replacement to avoid catastrophic failure. This includes anything made of plastic within the system. So far we have a few remedies - an aluminum radiator and a silicone coolant hose kit. The mechanical fan is next on our list to be addressed.

The stock fan setup is certainly efficient in keeping your straight six cool. That said, a fan failure can get quite ugly

-

Posted: October 13, 2014Categories: BMW 3-Series E30/E36 X-Line Radiator 1988-1999Continue Reading »

Interested in purchasing this BMW E30/E36 aluminum radiator? Check out the product page for more information!

Mishimoto BMW E30/E36 X-Line Performance Aluminum Radiator

The testing results are in! First, a quick comparison of the fluid capacity improvements the Mishimoto X-line radiator provides.

Stock Radiator Capacity: 0.6 gal (2.27L)

Mishimoto X-Line Radiator Capacity: 1.15 gal (4.35L)

This is an increase in capacity of 91%! This additional fluid, combined with our highly efficient core design, should easily produce great gains in cooling efficiency. Let's evaluate our charts obtained from the testing data. First up, our raw temperature data from both rounds of testing.