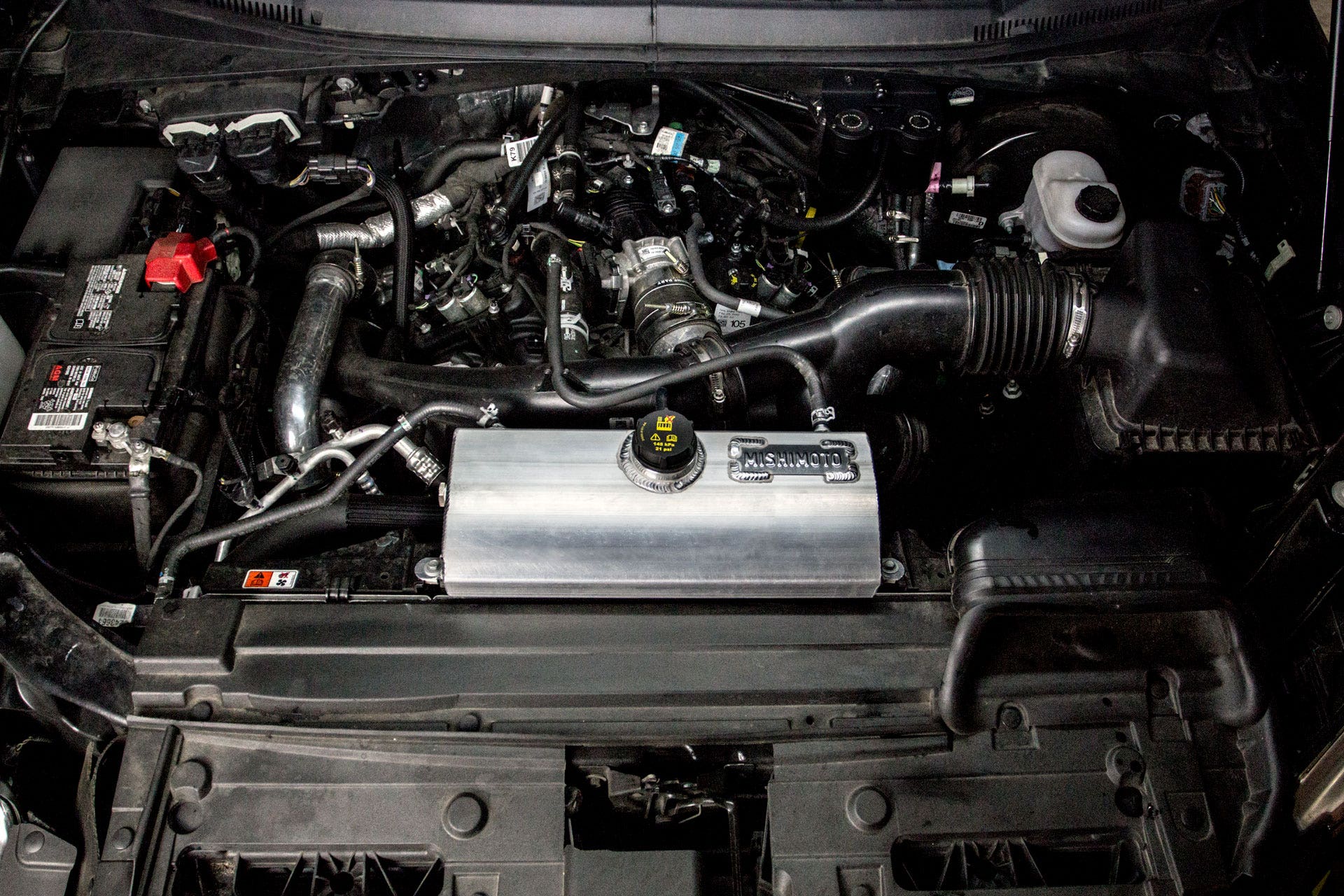

When we're talking about cooling the charged air in any forced induction vehicle, the intercooler always steals the show. To be fair, it is doing a majority of the work. No matter if you're still running a stock unit or if there's an all-aluminum core seated in the front of your car, it's the star. However, the intercooler would be nothing without the back-up band, the intercooler piping. Putting in all the effort to cool off the charged air would be useless without a method to transfer it to the intake. If the stock intercooler unit had some shortcomings, the piping was bound to end up with some flaws, too.

The safe passage for your charged air is currently left up to the combination of plastic and rubber construction that makes up the factory piping. It might seem that