Feed the Beast - 2012-2018 BMW F1X M5/M6 Performance Intercooler R&D, Part 1 - Stock Review and Design Plans

The term 'power hungry' typically isn't a great way to describe someone. This phrase carries a negative stigma for those willing to sacrifice it all to make their way to the top. However, when it comes to your executive sports sedan, this is precisely the descriptor that you'd want to hear, with the F1X platform BMW M5 and M6s being no exception.

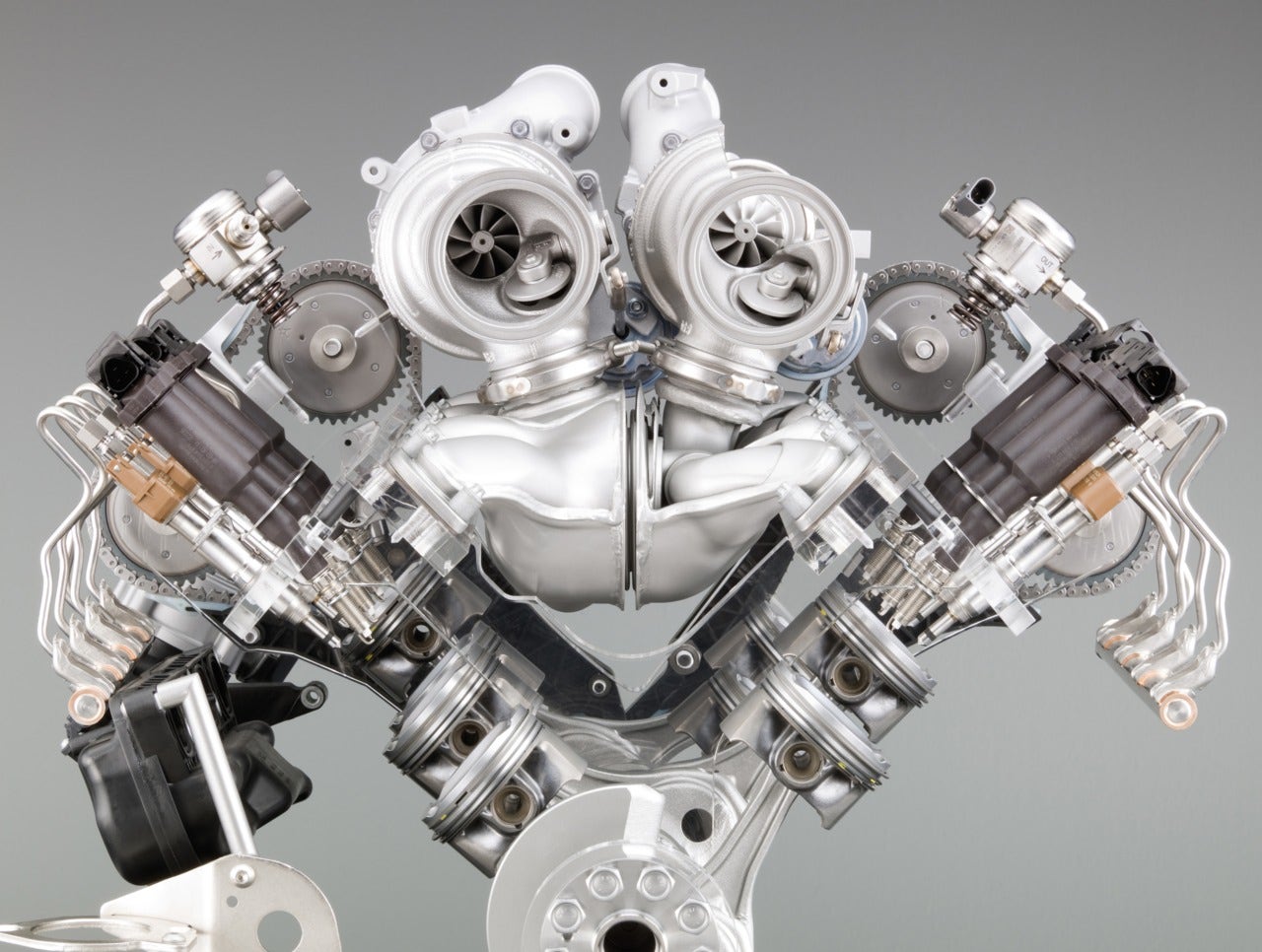

The S63 under the hood of these big M's isn't starved for power. In fact, it's quite the opposite. The stout 4.4L twin-turbo V8 rolled off the assembly line with 523 HP and 502 TQ crammed under the hood. However, even with this healthy dose of power, the M5 and M6 yearn for more speed, and we're happy to facilitate that need.

For forced induction vehicles, like the F1X M5 and M6, upgrading the intercooling system is critical for producing the best results from performance tunes or turbo upgrades. This system keeps your intake air temperatures lower to compress air into the cylinders better. Less efficient intercoolers will soak with heat much quicker, and cause those IATs to jump, ultimately making your M5 less of an ultimate driving machine. We already have a plan to keep these Ms running at peak performance, but first, let's look at the OEM design.

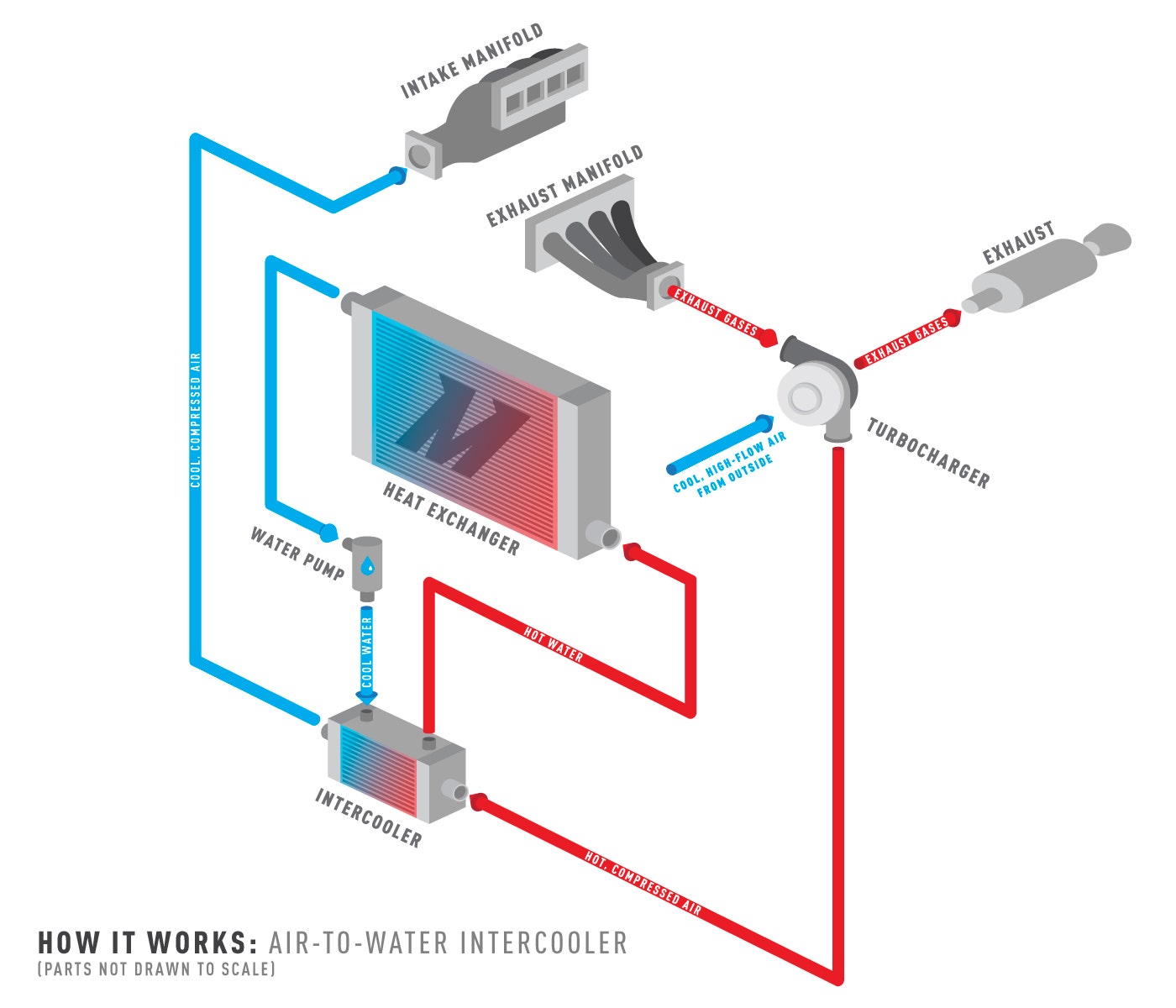

BMW already brought the intercooling system for this generation M5 and M6 to the next level by introducing an air-to-water system. For those unfamiliar with this concept, let's review.

The process of forced induction, meaning supercharging or turbocharging, is essentially compressing more air into the intake system, which creates that sweet boost pressure for more power. The drawback is that compression involves friction, which, in turn, creates heat. Gasses, like pressurized air destined for explosive results inside your engine, compress better when they're colder since the molecules condense. Hence the need for an intercooler

A heat exchanger is usually mounted front and center on the vehicle in a traditional air-to-air system. It utilizes the fresh air running through the grille to dissipate the heat from the charged air system. It's a simple concept, but its drawbacks include reliance on the vehicle to be moving to cool the air and requiring extensive, heavy intercooler cores to be specifically placed at the front of the vehicle for the best results.

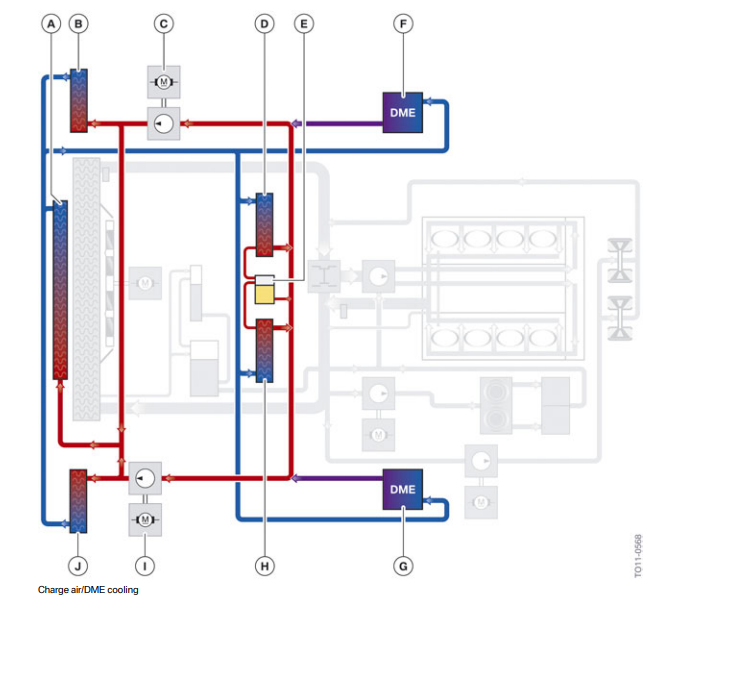

On the other hand, air-to-water systems are freer to roam around the engine bay. This system utilizes a secondary coolant system to whisk away the heat generated from building boost. Since water has a much higher thermal conductivity than air, the intercoolers don't need to be nearly as large for the same, if not better, level of cooling efficiency. Also, since the intercoolers aren't reliant on a fresh air source, they can be placed anywhere in the engine bay to maximize efficiency and reduce pressure drop through the system. The hot coolant is then circulated to a secondary radiator located in the cooling stack. This system is much more complex than the air-to-air system but still provides more efficient cooling even in OEM form.

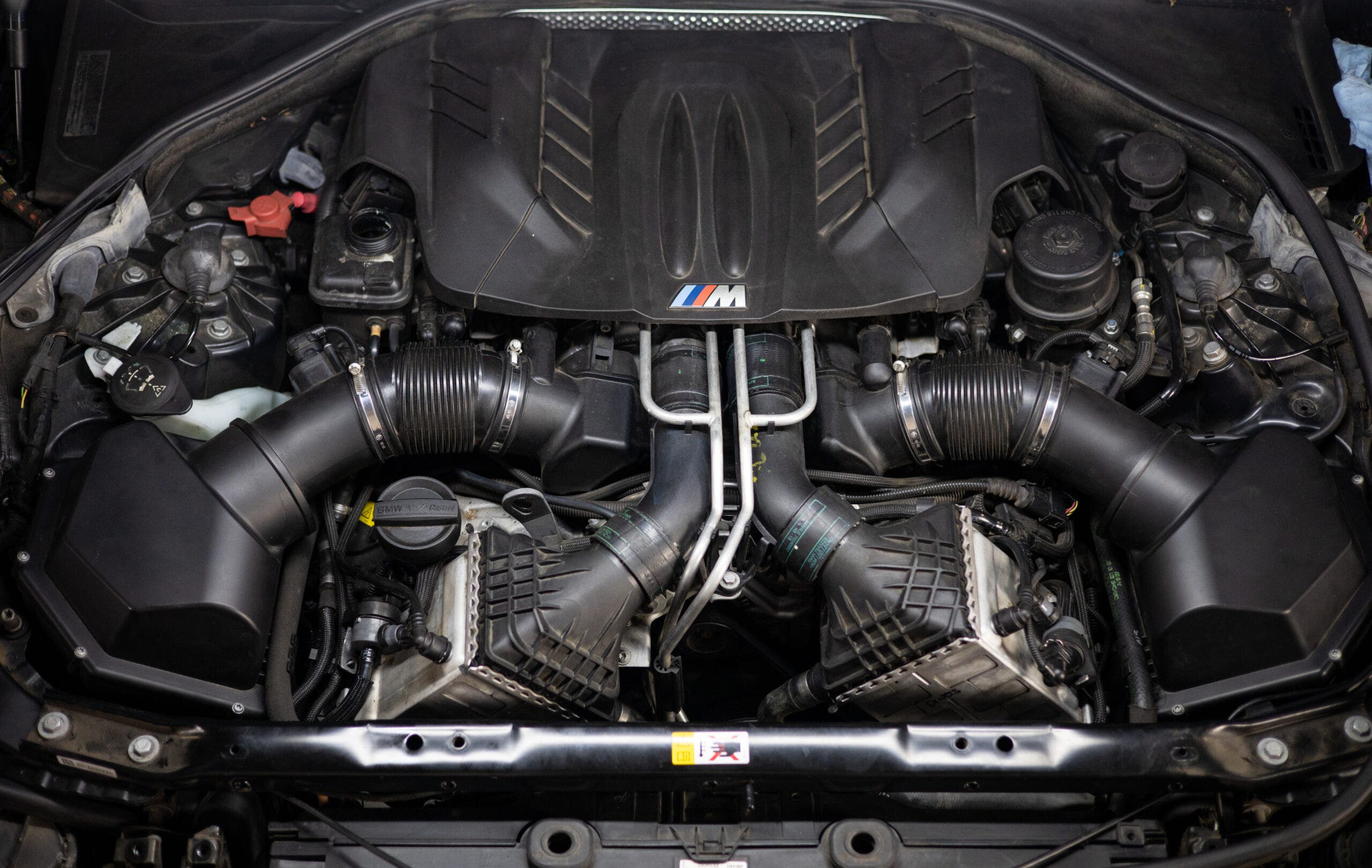

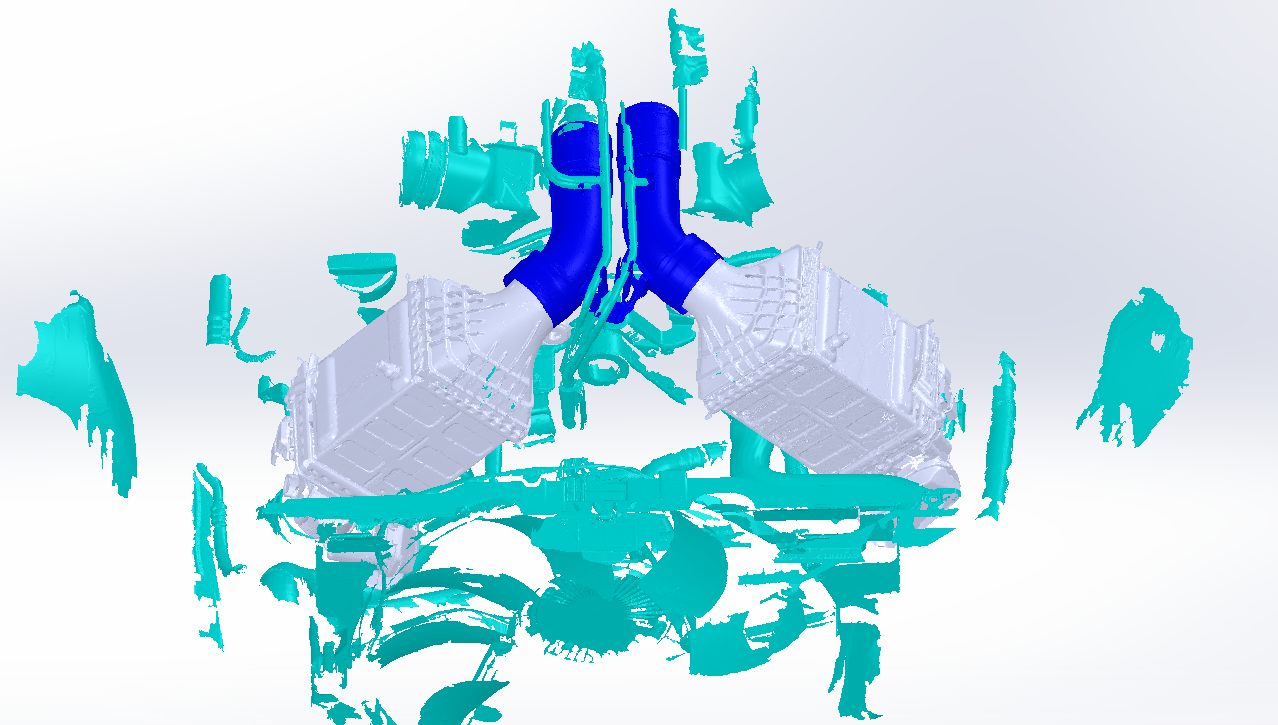

As well as an air-to-water system operates, there's still room for improvement, even when it comes to an ultimate driving machine blessed with the coveted M badge. For example, the S63 manages its intake air temperatures with not one, but two intercoolers that are on full display at the front of the engine bay. Having one intercooler per turbocharger divides up the cooling duties for a much more efficiently performing system, but BMW still had to make compromises for the sake of mass production.

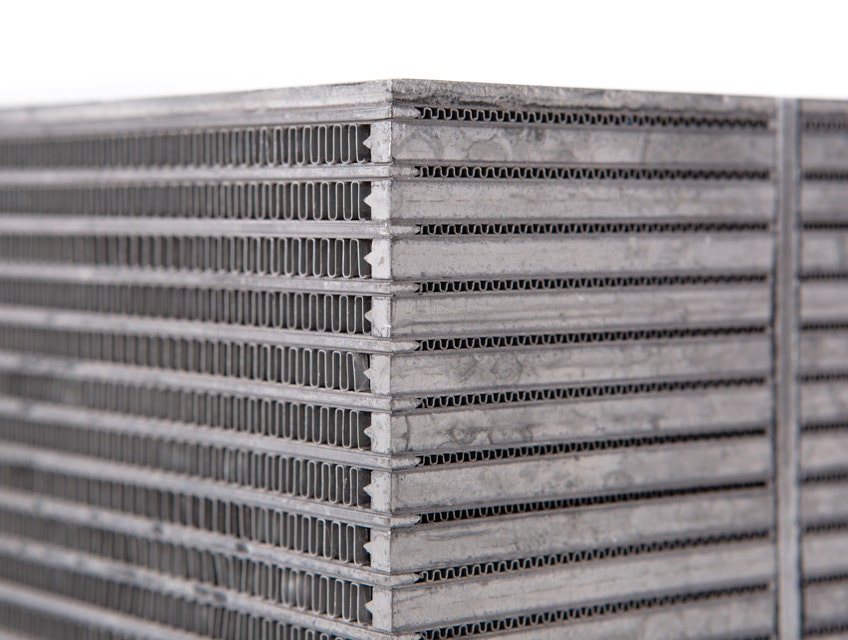

Water might have better thermal conductivity than air, but the lightweight tube-and-fin core still hampers the cooling process. This style of core construction is the perfect compromise between production costs and providing adequate performance for most daily drivers. However, tube-and-fin cores are more prone to heat soak and diminish performance.

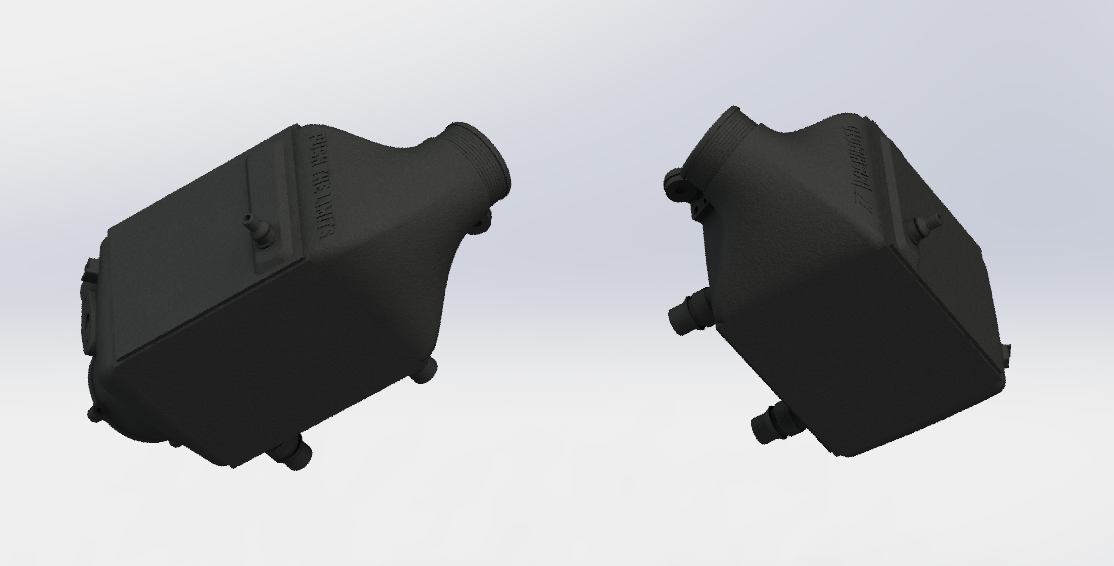

Durability is also questioned on two fronts of the factory setup, starting with the intercoolers' end tanks. Overall, plastic is a solid construction material choice for vehicle components and hits the right balance of cost and performance that BMW needs. However, the combination of heat and pressure over the years, coupled with any sort of performance enhancements, calls the longevity of these end tanks into question. In addition, cracks and leaks forming in these plastic end tanks are much more detrimental to the S63's performance than hot air, so we're already on the case to remedy that.

Speaking of cracks and boost leaks, if you know anything about BMWs from this era, you'll know about the Achilles heel that is weak charge pipes. Unfortunately, the F1X generation Ms are no exception to this epidemic, especially on our vehicle. The same heat and pressures working on the end tanks deteriorated our charge pipes and couplers, resulting in the same disappointing results.

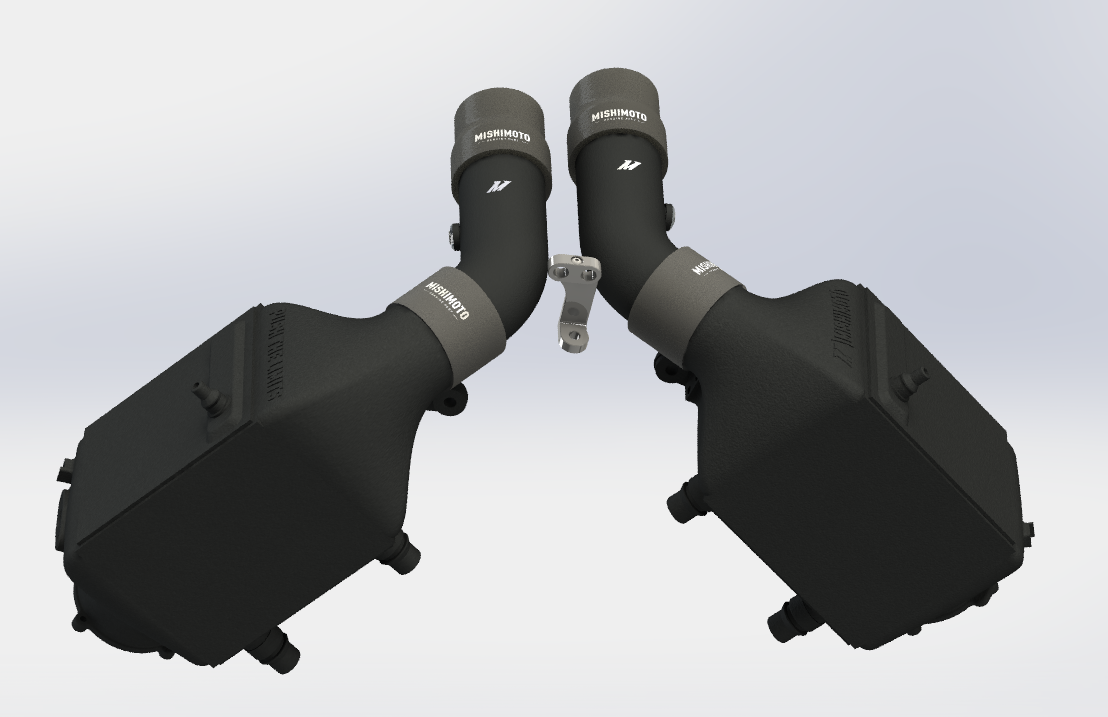

To mitigate the shortcomings that we've uncovered with our M5's system, we're planning on a full intercooling make-over. On the performance side of things, our engineer, Mitch, saw that the intercooler cores needed attention. Even though these air-to-water intercoolers are small but mighty, they can still be mightier. So to help facilitate the cooling process, we're swapping the tubes and fins for bars and plates. This heftier core design is more durable than its featherweight counterpart and is better suited for higher boost pressures and increased heat dissipation.

The core's construction is only half of the equation since size still matters even with air-to-water systems. BMW's engineers have always been masters and efficiently utilizing engine bay space, so core expansion was limited, but we still plan to add as much core volume as possible.

A complete core overhaul wouldn't be complete without a new set of end tanks for our intercoolers, especially since our cores are growing in volume. Our plotted course for these end tanks results in a combination of performance and durability. We're planning on casting our new end tanks from aluminum and TIG-welding them to our beefier cores for impeccable durability. This new cast design will also be optimized to increase flow through the intercoolers, ideal for vehicles demanding more boost from their S63s.

Finally, no intercooling system facelift would be complete without examining the charge pipes. Since the plastic and rubber OEM charge pipes are susceptible to degradation, we're opting for materials less prone to disintegrate over the years. Our new charge pipes are getting the metal treatment and will be mandrel-bent aluminum and integrate into the system with much more sturdy silicone couplers.

The beast underneath your M5's hood is already chock full of power. With that power comes plenty of potential for more. The S63 is, by no means, starved for power, but it's always hungry for more. Our plans to solidify the F1X's intercooling system are just one step closer to satiating that hunger. Make sure you stay tuned for the first look at our prototyping process.

Thanks for Reading!

-Nick