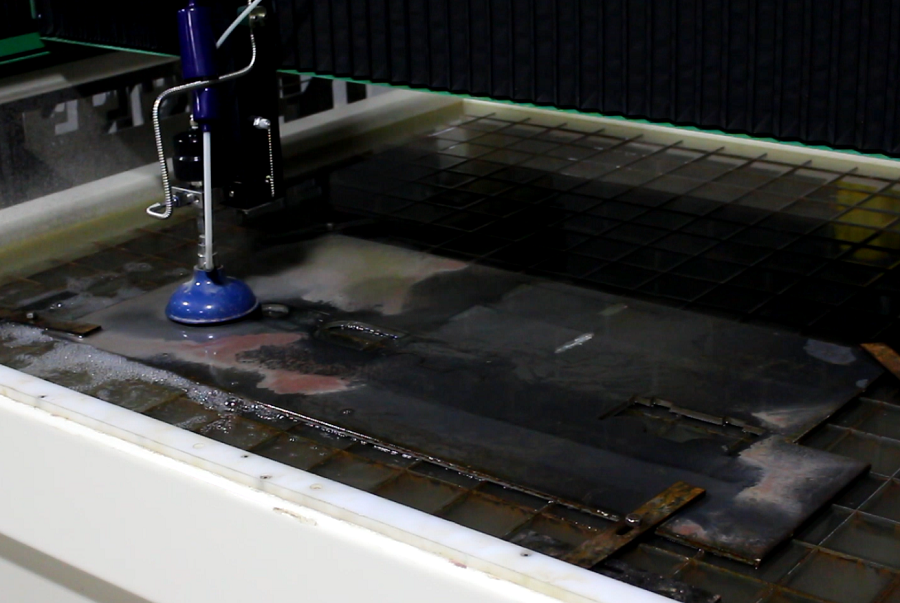

After coming up with a game plan we were ready to tackle the first portion of the Mustang GT exhaust, the resonator. We began this exhaust project a bit differently than projects in the past, we began with the waterjet.

How, you might ask, are we going to produce a prototype made of piping on the waterjet? We're not! To save time and improve accuracy, we will use a jig to create the first prototype H-pipe and X-pipes. Our hopes are that they will provide more precise prototypes that need less revision, therefore saving time. We will also use the same jig for production, so that each resonator delete produced will have the same great fitment as the prototype that we create.

With that said, we fired up the waterjet and began cutting our jig.

" width="640" height="426">

" width="640" height="426">