Last time we wrapped up our first attempt at creating an accurate gauge for measuring strut tower flex. Our initial tests showed some inconsistencies, which have been attributed to the method by which we mounted our gauge.

These inconsistencies occurred most likely because of the difference in materials. Our strut bar is steel, whereas the gauge assembly is aluminum. Welding these materials together is not possible, so we used alternate methods.

We need to eliminate any adverse variables for this test. Measurements of movement are small, so even a seemingly insignificant issue could cause skewed data. We decided to work up a full aluminum prototype modeled after our first design.

All-Aluminum Strut Bar Testing Prototype

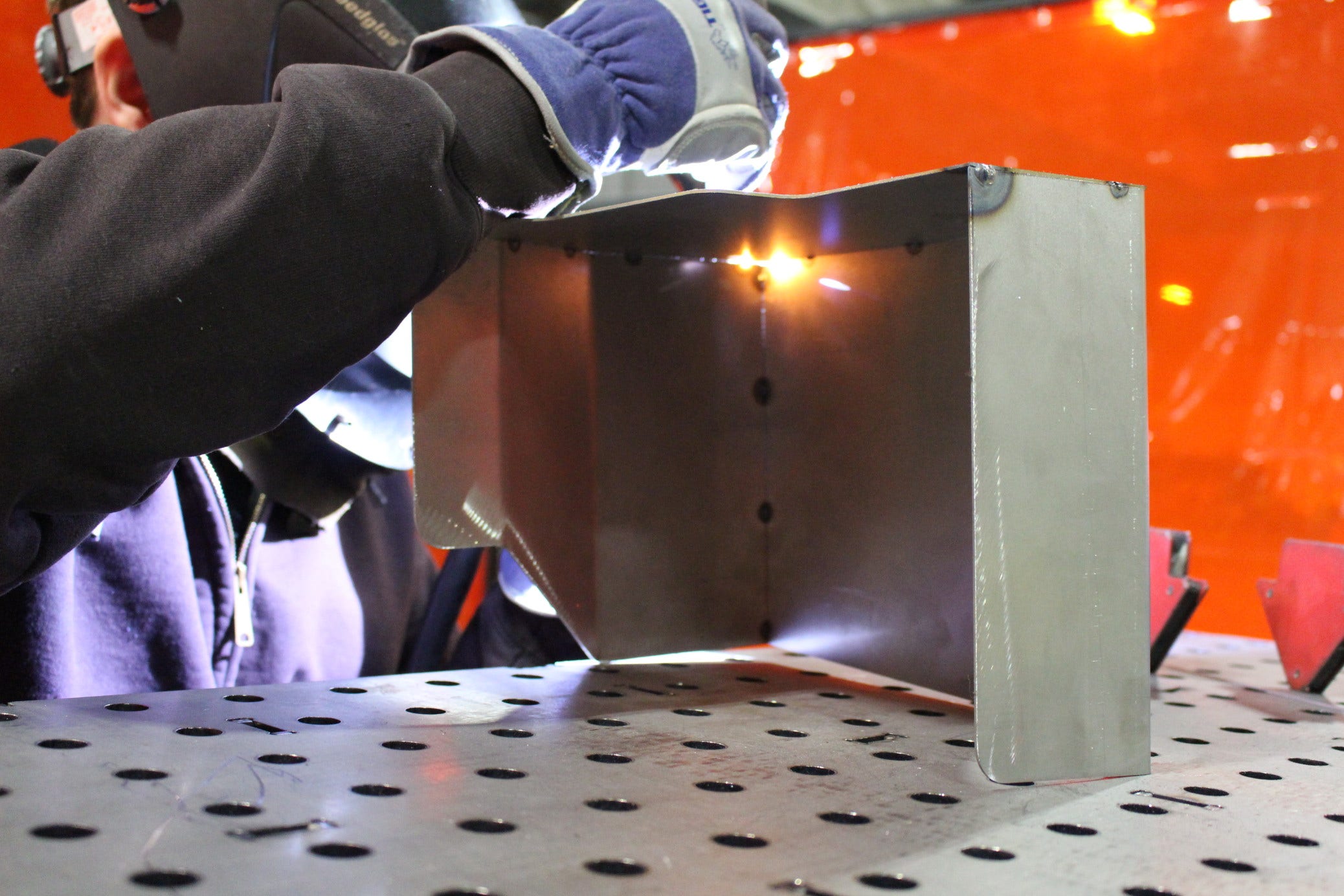

In addition to new machining tools, we have a new high-pressure Waterjet cutter here at Mishimoto. We decided to flex its muscles a bit and use it to cut out our strut bar brackets. These were then welded to the bar itself

Fiesta ST expansion tank

Fiesta ST expansion tank Fiesta ST expansion tank

Fiesta ST expansion tank

Prototype Subaru Forester parts

Prototype Subaru Forester parts