The Mustang EcoBoost Intercooler, Part 5: Finished Product and Final Testing Data

Interested in picking up this awesome Mustang EcoBoost Intercooler? Check out our product page for more details!

Mishimoto Mustang EcoBoost Performance Intercooler

Mishimoto intercooler

Thanks to everyone who has followed our journey thus far. With a ton of testing and design work complete, we finally had our intercooler design ready for testing. We've leaked a few cool shots on the forum; check out more of the detailed images below.

Mishimoto Final Design

Mishimoto intercooler final design

Mishimoto intercooler final design

And a couple shots of the end tanks and inlets. As noted in our previous post, these tanks are constructed from cast aluminum and feature an internal diverter to improve airflow dispersion. The mounting components and inlets are CNC-machined for precision purposes.

Mishimoto intercooler end tank

Mishimoto intercooler hot-side inlet

Mishimoto intercooler hot-side inlet

In order to provide factory-like fitment, we had to incorporate the pressure sensor port on the cold-side of the intercooler. Check it out!

Mishimoto intercooler cold-side inlet with temperature sensor

And finally, take a look at the core we designed for the EB!

Mishimoto intercooler core

This cooler will be powder-coated and available in the silver you see above, as well as a Stealth Black finish. The next shot shows the progression of development from the stock cooler, to our 3D-printed prototype, and finally our completed design.

Mishimoto intercooler progression

Size Comparison

So how much bigger is it? This is the most common question of folks surfing around for the best intercooler possible. Although slapping a giant cooler on your Mustang isn't the absolute answer for performance, increasing cooler size is one way to achieve greater heat transfer and cooling performance. Check out a few shots of our cooler next to the stock unit.

Mishimoto intercooler (top) and stock intercooler core (bottom)

Mishimoto intercooler (top) and stock intercooler core (bottom)

Let's put some numbers behind the actual increases in volume and thickness that our core provides.

Installing intercooler prototype

Mishimoto intercooler installed

We then checked fitment with the active grille-shutter system.

Mishimoto intercooler installed with grille-shutter system

And here's a shot of the charge-air cooler (CAC) piping connections!

Mishimoto intercooler installed

Dyno Testing

Intercooler dyno testing

Intercooler dyno testing

It was time to collect some testing data for our new cooler design. Our primary data points (as with any intercooler) would be the intake temperatures, both pre- and post-intercooler. We would be comparing data between the stock intercooler and our prototype. We would also be evaluating any differences in pressure loss with our cooler as well as any power gains we are able to achieve with simply bolting the cooler into position.

We installed our AEM sensors, booted up the software, and began making pulls. Check out the video below featuring clips from the dyno testing.

Intake Temperature & Efficiency Comparison

The first comparison to make is in terms of intake temperatures. Please reference the chart below!

Intake temperature results

The difference in temperature drops between the stock intercooler and the Mishimoto are quite substantial. The chart above depicts a 4th-gear pull on our dyno in our shop, which was at 58°F (14.4°C) on this particular day of testing. The chart below summarizes the peak numbers for each plot.

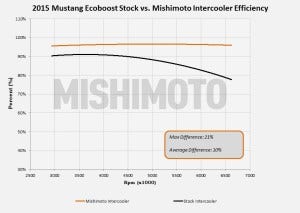

Intercooler efficiency comparison

As expected from reviewing our temperature data, the Mishimoto intercooler provides improvements in efficiency. The Mishimoto cooler averaged around 96% efficiency, while the stock cooler averaged 86%. Toward the end of the pull you can see the stock intercooler drastically lost efficiency. This loss will only be compounded during a track session or a hot day.

The external fin surface area of our intercooler is one of the primary contributors toward improved heat transfer.

External fin surface area comparison

We've increased fin surface area by 165%, which provides great contact points for heat transfer and allows us to take full advantage of airflow passing through the core.

Pressure Loss

Next, we took a look at pressure loss across the core. We wanted to be sure that our dense intercooler was not inhibiting flow and producing a large amount of pressure loss.

Intercooler pressure drop comparison

As you can see, the Mishimoto intercooler does indeed see a slight increase in pressure drop across the core. This is a result of our larger volume and increased internal fin density. Both of these factors result in around a 1 psi greater loss through the upper rpm range. This is relatively small and will not cause any concerns. As we noted earlier, we have to balance pressure loss and efficiency benefits in order to provide a well performing product.

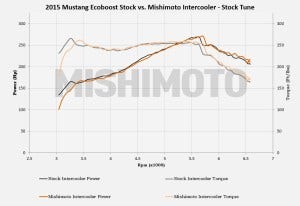

Power Output Comparison

Intercooler upgrades are typically a supporting modification. This means that as you bolt on upgrades, both power and heat are generated. To support the additional power, an upgraded intercooler can provide lower intake temperatures which can result in power gains with ECU tuning. On the stock tune, it is rather rare for substantial gains to be made. Our plot is shown below.

The chart above shows an average for each intercooler. We did not skew our data and select the best/worst runs to produce bigger gains. Gains with the Mishimoto cooler are somewhat negligible, with 1–3 whp gains at different points within the powerband. The true power gains will come about when this vehicle is tuned with a more aggressive timing curve to take advantage of the lower intake temperatures. We highly recommend doing so!

Conclusion

This concludes out project! We have a very robust, efficient intercooler solution for the EcoBoost Mustang. A summary of the testing results are noted below.

- 30°F–35°F drop in outlet temperatures

- Intake temperatures held at no more than 7°F above ambient

- Minimal pressure drop

- Average efficiency of 96%

- 165% increase in external fin surface area

- 58% increase in core volume

Who's ready for a discounted presale?

–John