Our quest for the perfect intercooler core continues! So far we've perfected the fitment and size of our intercooler core. Our final task is to adjust internal fin composition to create a perfect blend of pressure retention and temperature benefits.

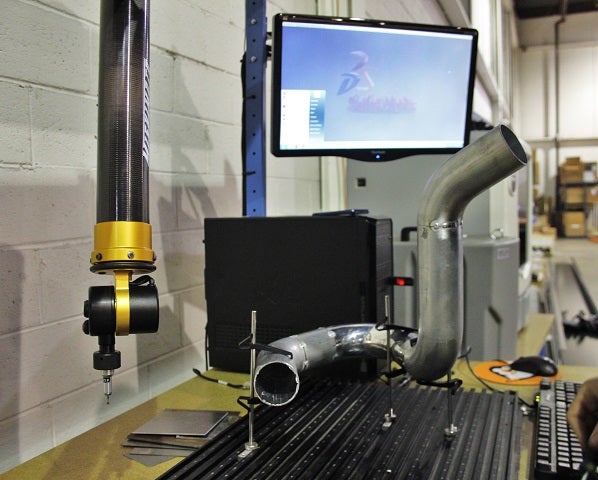

Prototype Ford Fiesta ST Intercooler Fabrication

Timing is a bit of a concern for us at this time. This project has been lengthy, but it will be worth the effort and time when we know our best efforts have been captured in our final product.

Our final version of this intercooler will likely feature a tube-and-fin core. The benefits of weight and airflow are too important to ignore, not to mention the temperature drops we are seeing with a strategically designed internal core.

For our team, the creation of a bar-and-plate cooler is a much quicker process. We've found that pressure drop between the two core types is similar if fin style, density, or both are the same. So for this test, we are using two bar-and-plate

" width="300" height="180">

" width="300" height="180">