Honing the Blade - 2016+ Polaris RZR XP Turbo Performance Intercooler R&D, Part 1 - Stock Review and Design Plans

Much like the sharpened blade that it takes its name from, Polaris's RZR is a purpose-built tool designed specifically for making precise cuts through the rugged wilderness. The 925cc torquey twin paired with forced induction, knobby tires, and long-travel suspension, all placed neatly in a fun-sized chassis makes this side-by-side the ideal specialty tool for off-the-grid excursions. Much like an actual razor, though, this machine needs constant honing to retain its sharp performance, and in this case, our whetstone is the intercooler.

The OEM intercooler is one aspect of this rugged rig that can dull the performance of your turbocharged RZR. Of course, it's not necessarily in terms of cooling power. Still, the high demand for this vehicle across treacherous terrain knocks this intercooler around enough, which can lead to cracks and leaks in the charged air or, worse, the coolant running through the core.

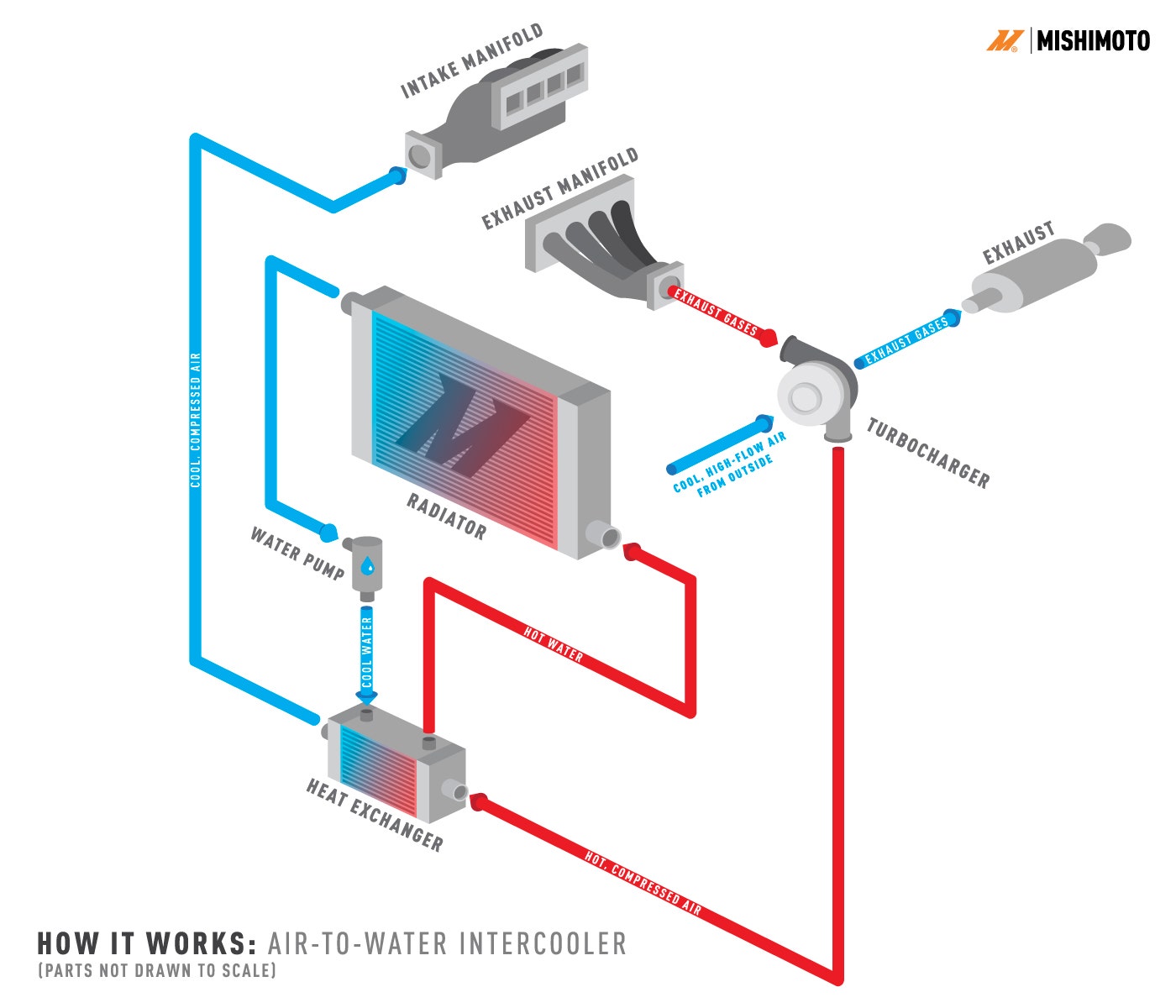

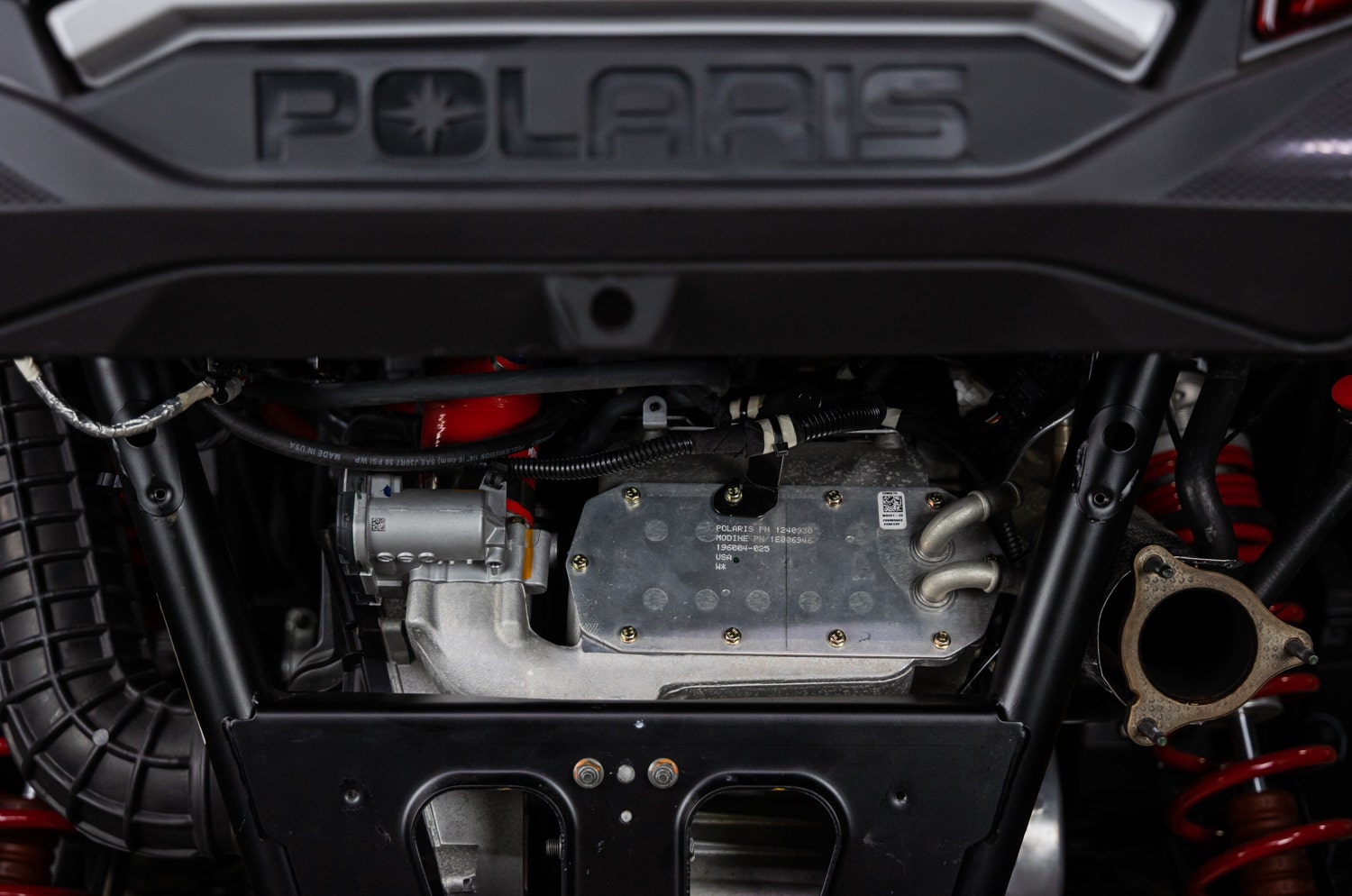

The RZR utilizes an air-to-water intercooler system from the factory, with the intercooler mounting directly in the intake manifold and the auxiliary heat exchanger mounted front and center of the RZR's cooling stack. This setup might be second nature for some of you, but for those scratching your head, here's the crash course.

In forced induction vehicles, like the turbocharged 925cc twin at the rear of your RZR XP Turbo, an intercooler is vital for optimal performance since compressing air for boost inherently generates heat. Intercoolers remove heat from the charged air with one of two methods: air-to-air or air-to-water. Both methods perform the same function, and you can learn more about the intricacies of each system in our tech post, but in this case, a secondary cooling system is used to maintain the intake air temperatures. However, this setup is highly effective for applications like this Polaris, but it's a double-edged sword since damaged cores equate to boost leaks, coolant seeping into the intake tract, or both.

To optimize the RZR's performance, Polaris designed the intercooler essentially as a cartridge that slots directly into the vehicle's intake manifold. Inserting this fluid heat extractor so close to the engine's intake valves is advantageous for reducing turbo lag giving this peppy off-roader a much better power response for digging out of tricky situations. However, while beneficial for performance, the presence of a fragile fluid-based cooler so close to the combustion chamber poses risks to the peppy turbo twin.

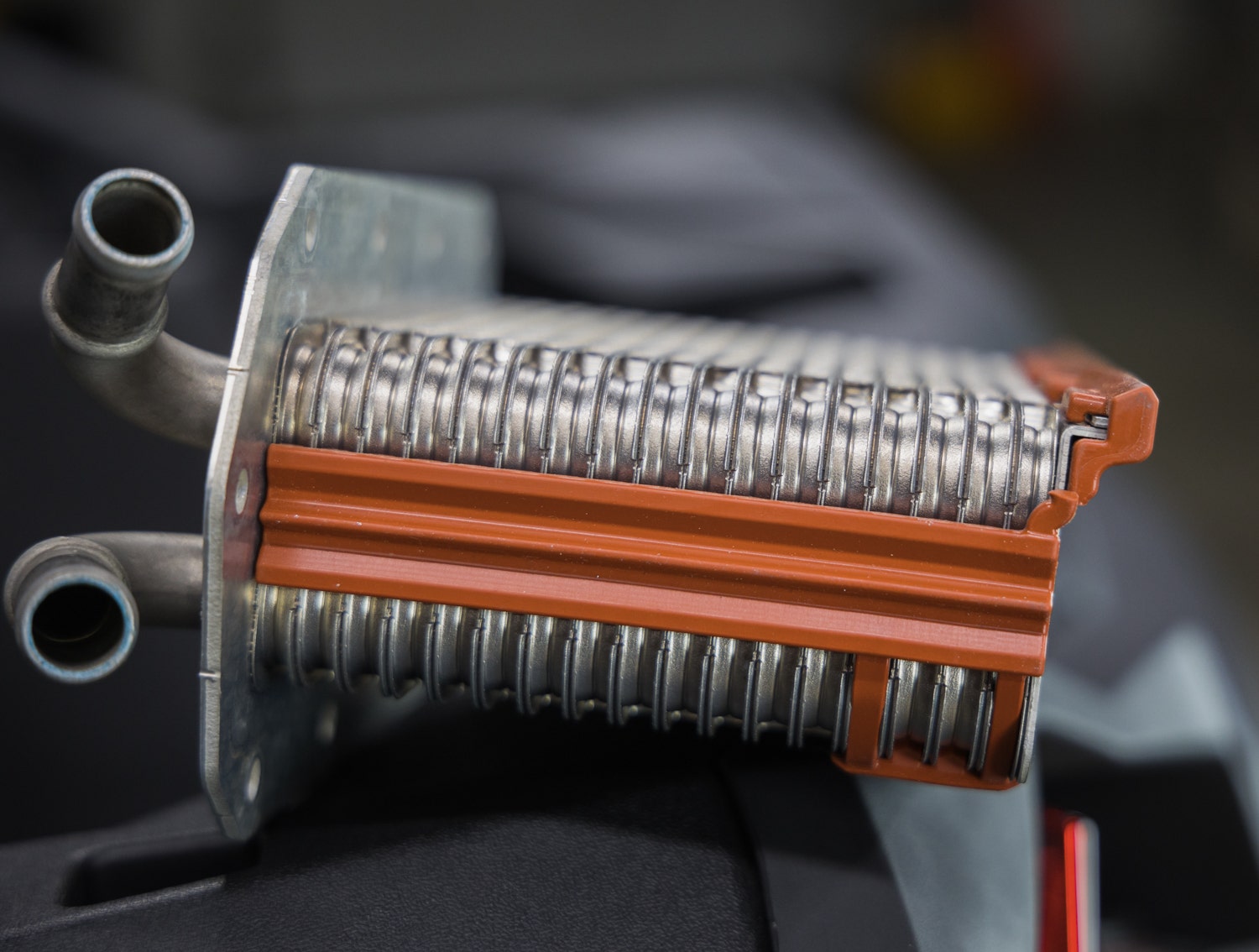

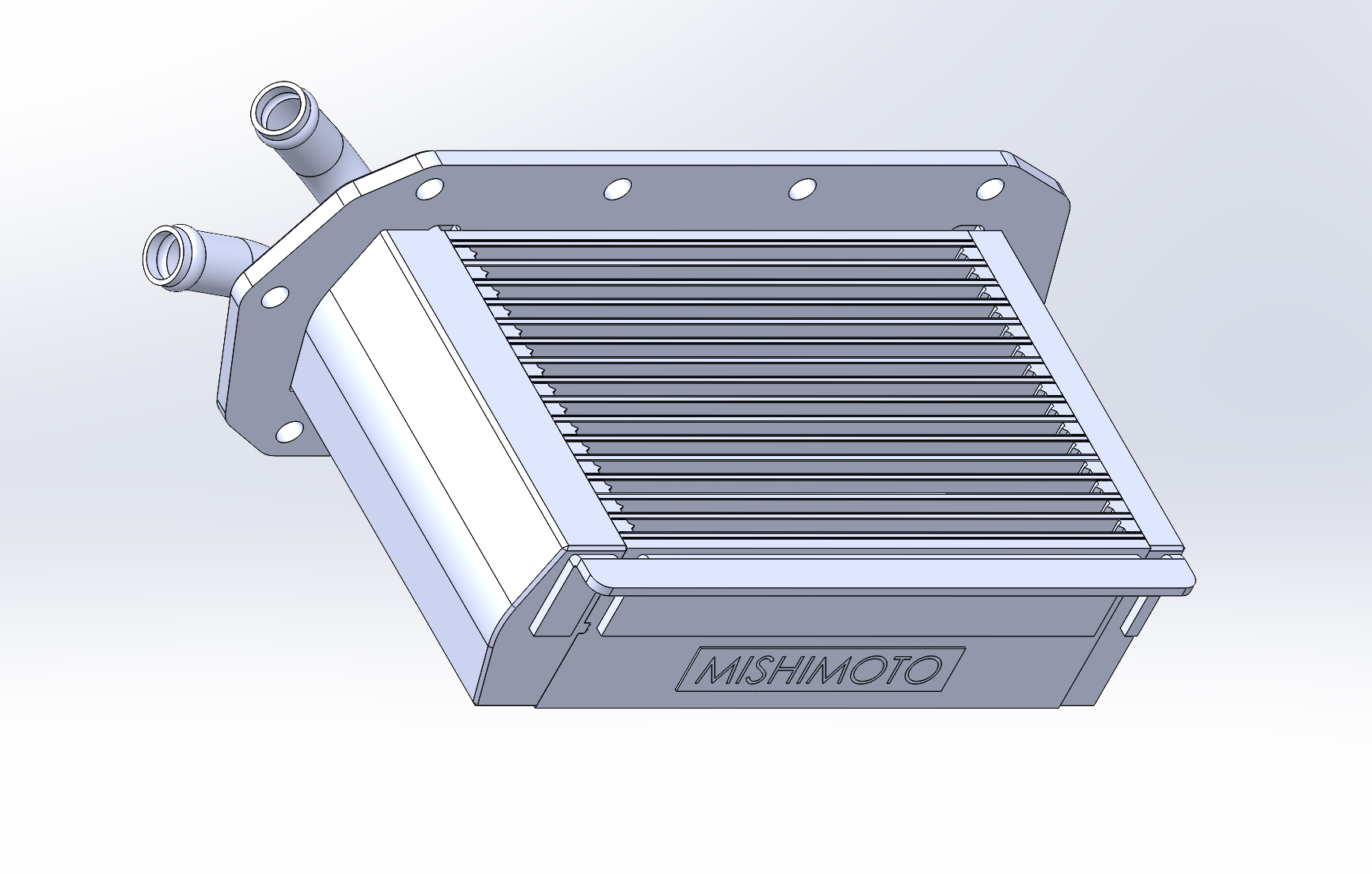

Once we extracted the intercooler from the RZR's intake manifold, we found essentially a pair of plate-and-fin liquid coolers linked together to create a dual-pass fluid flow through the core. The construction of this intercooler core is the ideal balance for reduced production costs and adequate cooling of your RZR's charged air.

Plate-and-fin coolers are a common and effective heat exchanger more commonly utilized for maintaining transmission fluid temperatures on a wide array of vehicles. This cooler style is also highly versatile, which is why we find it inside the RZR's intake manifold. The inexpensive and lightweight construction, however, does make them much more prone to spring leaks when they have jostled around in something like an adventure-ready side-by-side.

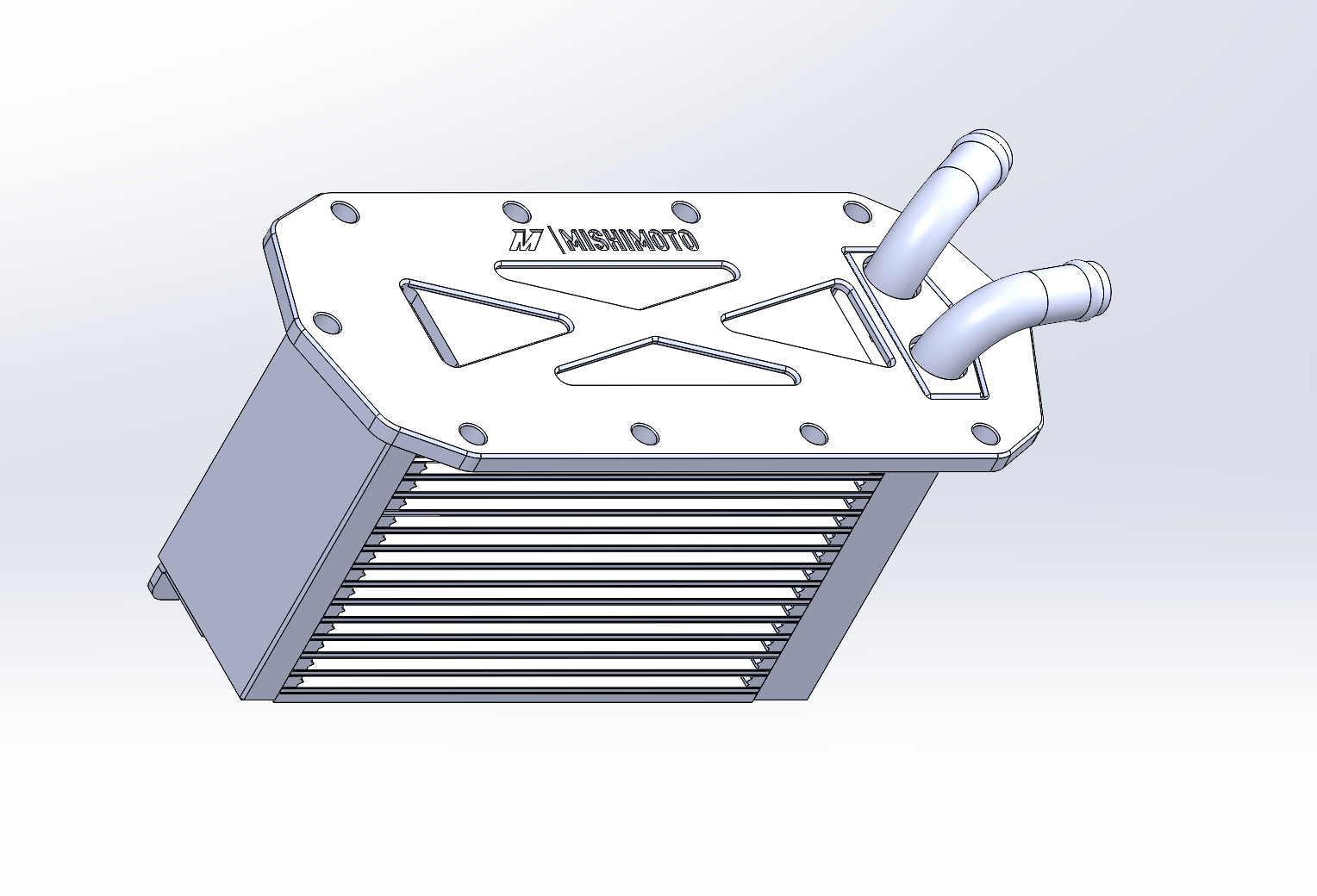

Since we're locked into a very specific build envelope, given the RZR's intercooling system, increasing the size of this intercooler core is not an option. In that case, design improvements come down to updating the core's construction. Where the plate-and-fin coolers aren't quite up to snuff for the RZR's intended purpose, the bar-and-plate core construction will provide a much more sturdy heat exchange for the charged air. To further improve the dependability of the RZR's intercooler, we're planning to incorporate a pair of billet aluminum end tanks into our design that will be TIG-welded to the core.

While maximizing cooling performance isn't the primary goal of this venture, it can be a beneficial side-effect of our proposed design. For starters, we intend to retain the dual-pass fluid path with our core for a more even and effective heat transfer when combined with the bar-and-plate core. In addition to providing a more reliable heat exchanger, bar-and-plate cores are better suited for resisting heat soak.

Nothing diminishes peak performance quite like defective or unreliable components. Polaris named its muscley side-by-side after one of the sharpest tools out there, but the risk of leaky intercooler can dull the sharpness of the rugged off-roader. Stay tuned for the first look at our prototype design coming soon.

Thanks for Reading!

-Nick