As Ye tightened the last bolt on our intake production sample, we breathed a sigh of relief. Over a year of painstaking R&D came to a close with that bolt.

In all our years designing intakes, few have been as complex or demanding as our 2018+ Jeep Wrangler JL 2.0L intake. We've fought check engine lights, tested more variations than we could have imagined, and learned a lot along the way. But the time is finally here to see the product of our efforts in its final form.

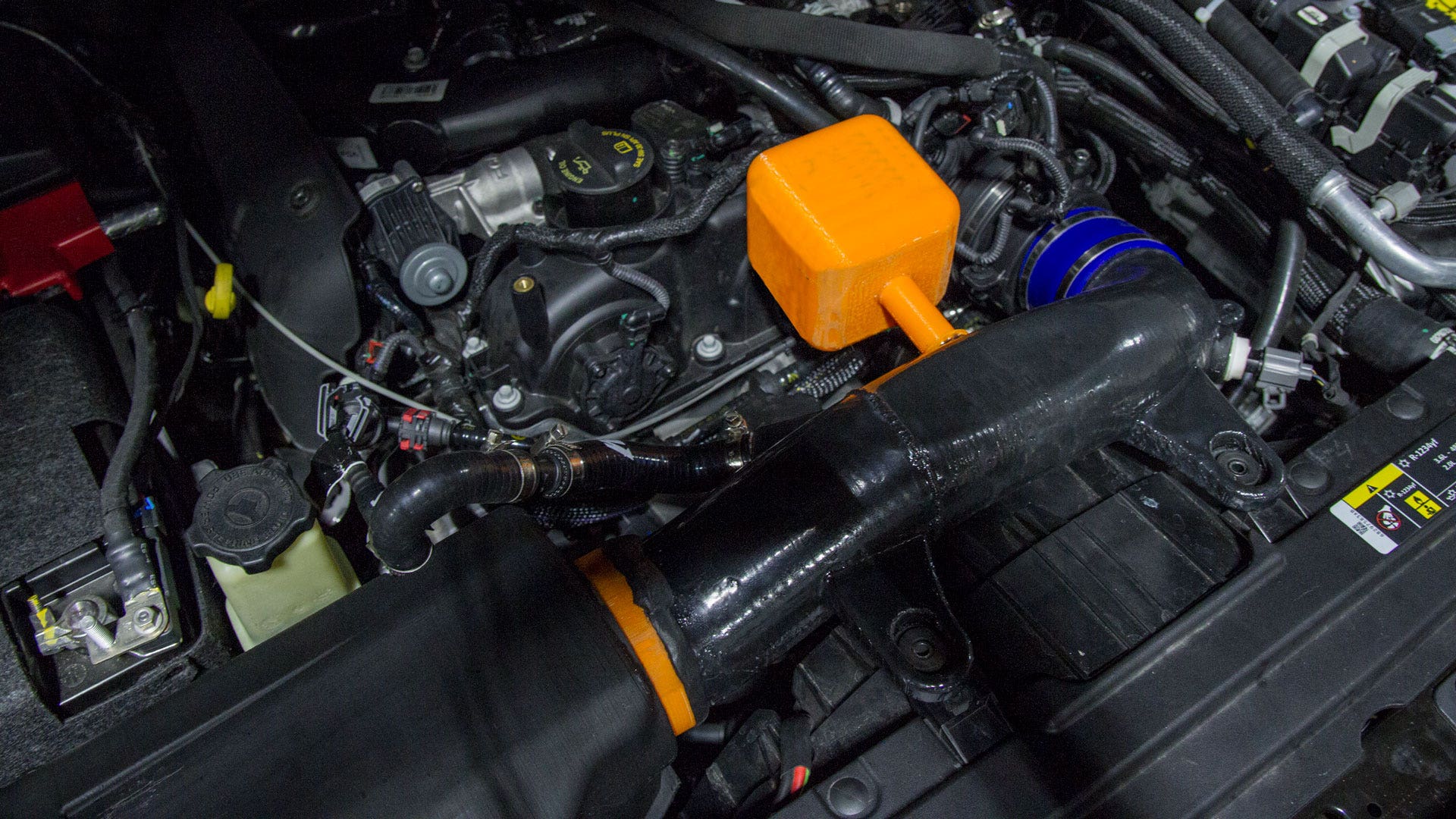

Shortly after we finished our final design from the last post, we began production on a sample to test fit. This test fit is the final (and often the most crucial) step in the R&D process. It tells us if our