A More Durable Degas. Mishimoto's Ford Powerstroke 6.0L Aluminum Degas Bottle R&D, Part 3: 3D-Printed Prototypes

With a rough 3D model in place, we started constructing our 3D-printed prototypes to finalize our 6.0L degas bottle design and to refine any areas where adjustments are needed.

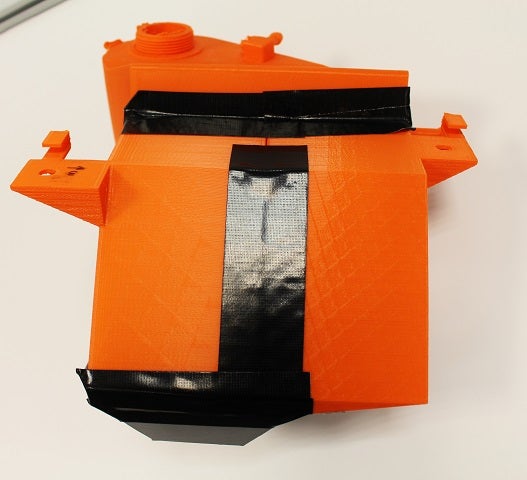

Due to the large size of this degas unit, we printed the bottle in multiple sections and then attached each portion together.

Below is a look at our first 3D print fitted into place on our 6.0L.

3D-printed 6.0 Powerstroke degas bottle

3D-Printed 6.0 Powerstroke degas bottle

3D-printed 6.0 Powerstroke degas bottle

Our first prototype needed some work. The rear portion of the bottle had clearance concerns, so we adjusted and tweaked a few of the faces of our design.

3D-printed 6.0 degas bottle

3D-printed 6.0 degas bottle

The big change we needed to make to this design was the angle of the rear portion of the bottle.

3D-printed 6.0 degas bottle

Adjustments were made to the design, and we printed a second 3D prototype. I wonder if our printer is beginning to feel used and abused. Do 3D printers have feelings?

Check out our second prototype unit.

3D-printed 6.0 Powerstroke parts

3D-printed 6.0 Powerstroke parts

3D-printed 6.0 Powerstroke parts

Once assembled we installed this prototype in the truck and checked all the clearances.

3D-printed 6.0 Powerstroke parts

3D-printed 6.0 Powerstroke degas bottle

For the most part this unit fit quite well. After a couple more minor adjustments, our team was pleased with the end result in fitment and projected appearance.

Coming Up - Functional Prototype

Now that we have a concrete design, our team will be constructing an aluminum prototype to check both fitment and functionality.

Thanks for reading!

-John